Vacuum deposition・Sputtering

Vacuum deposition and sputtering technique which is the root of MSK.

MSK’s production technology which was born from High technology and Nano technology

MSK operates vacuum deposition and sputtering that applies special coating layer on surface of Plastic・Glass.

Vacuum deposition for Plastic

Vacuum deposition for Glass

Vacuum deposition

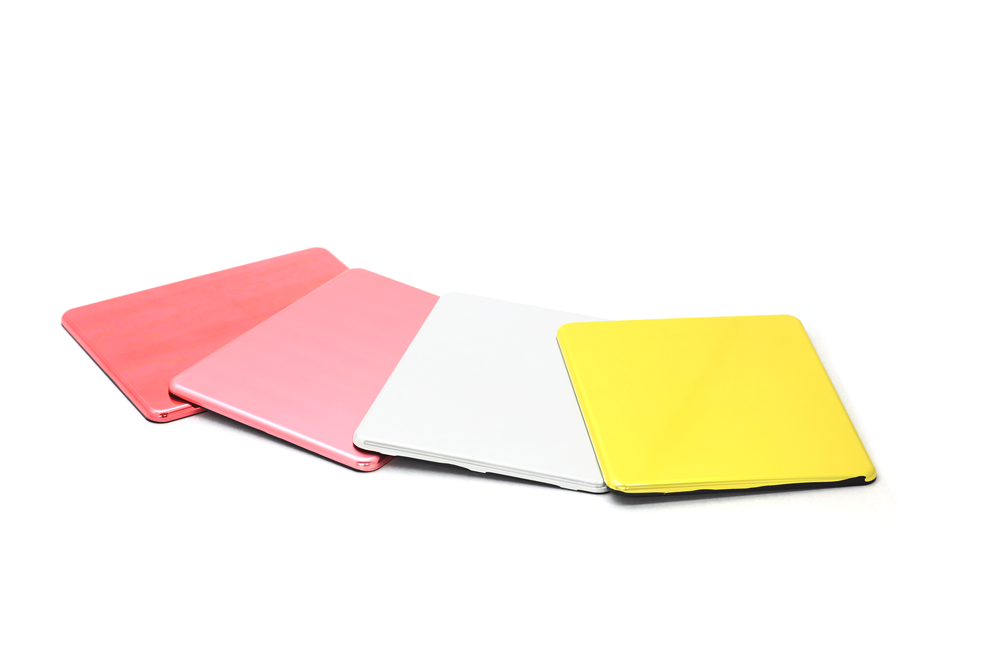

Vacuum metalizing image

This is the method of vacuum metalizing that evaporating or sublimating the target material by heating to put it on the sheet or film which has low temperature and then make it concentrate. If you heat metal intensively in air, it will be oxidized and crumble. All process is conducted in a vacuum which made by special machine there is no impurity like dust. Also all target material put on the sheet or film with same direction, so it makes its finish smoothly. Any kinds of materials (glass, titanium and so on) can be used for target material.

Surface treatment for Plastic

Anti-Reflection

Achievable less than 0.5% reflection with very high transmittance.

Reflection spectrum and water repellent finish are available for customize.

Also Anti-Fingerprint coating is available to be added on the top surface.

Dielectric multilayer mirror

Stacked dielectric layers composed by different refractive index on each layer controls spectral reflectance. This technique enable the layers to get less light absorption that creates higher reflectance (available both reflectance and transmittance) which is a function not available in metal layer.

Metal mirror

This is a mirror effect layer comes with strong adhered metal such as Aluminum・Nickel・Chrome. Metal layer is available in half mirror or full mirror which are created by fine pitch coating layer control technique.

NCVM(非導電)

Mirror

NCVM is a coating technology creates mirror like non-conductive metal layer that doesn’t make effect on radio wave or capacitive touch panels.

Surface treatment for Glass

Anti-Reflection

Achievable less than 0.5% reflection with very high transmittance.

Reflection spectrum and water repellent finish are available for customize.

Also Anti-Fingerprint coating is available to be added on the top surface.

dielectric multilayer mirror

Stacked dielectric layers composed by different refractive index on each layer controls spectral reflectance. This technique enable the layers to get less light absorption that creates higher reflectance (available both reflectance and transmittance) which is a function not available in metal layer.

Metal mirror

This is a mirror effect layer comes with strong adhered metal such as Aluminum・Nickel・Chrome. Metal layer is available in half mirror or full mirror which are created by fine pitch coating layer control technique.

ITO

MSK ensures ITO pattern remain invisible which is necessary for LCD application. Our ITO is adjustable low resistance, durability, uniformity.

Metal electrode

MSK creates a metal electrode that adjusts touch panels, electrode, wires in FPD by Variation of metal membrane.